During his tenure as the Marine Corps observer to Springfield Armory, Melvin Johnson Jr. concluded that the Garand and Pederson rifles on test there both had flaws in design and would be difficult to mass produce. Johnson set about designing a rifle that would be reliable, accurate and easier to manufacture. So in 1935 he produced his first working model of a rifle using a delayed blowback system of operation. This first rifle was made from scrap firearm parts and had a knitting needle for a firing pin. Despite these rudimentary beginnings, the design worked fairly well but needed major refinements.

Johnson's first prototype rifle of 1936

On September 28 1937 Johnson's first U.S. Patent, number 2,094,156 was granted. The first of over a dozen different US patents concerning firearms (and bayonets for them).

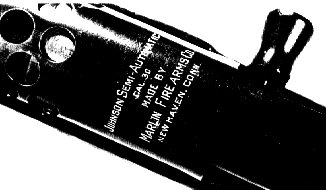

This refined weapon now operated on a retarded

recoil system. Using his Patent, he and Marlin Firearms of New Haven Conn.,

produced prototype military specification rifles which were submitted to

the Army Ordnance Board for evaluation at the Aberdeen Proving Grounds, MD in August 1938.These

first tests were fairly successful, but some weaknesses were found in the

design. These were quickly rectified by Johnson. These refinements led

to new Patents for Johnson, numbers 2,146,743 modified the bolt and extraction

system, and 2,181,131 brought changes to the cocking handle and the extractor.

This latter Patent made it possible to remove the extractor from the weapon

while still leaving the bolt in place. A new rotary magazine was introduced

to replace the vertical box magazine which had proven weak under testing,

though the vertical box magazine model was still available to potential

customers. The two types were identified by using the initial V (vertical)

or R (rotary) to differentiate the magazine types. Detail

of Marlin a manufactured receiver

for evaluation at the Aberdeen Proving Grounds, MD in August 1938.These

first tests were fairly successful, but some weaknesses were found in the

design. These were quickly rectified by Johnson. These refinements led

to new Patents for Johnson, numbers 2,146,743 modified the bolt and extraction

system, and 2,181,131 brought changes to the cocking handle and the extractor.

This latter Patent made it possible to remove the extractor from the weapon

while still leaving the bolt in place. A new rotary magazine was introduced

to replace the vertical box magazine which had proven weak under testing,

though the vertical box magazine model was still available to potential

customers. The two types were identified by using the initial V (vertical)

or R (rotary) to differentiate the magazine types. Detail

of Marlin a manufactured receiver

The Taft-Peirce Company of Woonsocket, Rhode Island, who were making commercial sporting grade rifles for Johnson, was now contracted to make seven trials guns containing all of the modifications for further Army tests. These rifles cost $3500 each to make. The sporting grade guns were produced containing such civilian market refinements as checkered stocks, recoil reducing butt plates and provision for scope mounting.

(Below) Johnson Sporting Rifles made

by Taft-Peirce Co.

The Army Ordnance Board trials commenced in December 1939, again at Aberdeen. Using Taft-Peirce manufactured rifles, over 6,000 rounds of ammunition were fired with only 12 minor stoppages experienced. These tests found that although the Johnson rifle was well made, it was not suitable for Army use.The Ordnance Board stated in their report of the trial dated February 23 1940, that the rifle was too long and heavy for their requirements and that it would not function reliably with the bayonet fitted. The magazine was considered delicate and its design would allow the ingress of sand and other debris into the action, causing stoppages.

Having suffered a set back with his hopes of acceptance by the Army, Johnson set his eyes on the Marine Corps, which still had doubts on adopting the Garand as their new semi-automatic rifle. Initial trials were held at Quantico Marine Depot, Virginia, in May of 1940. This trial was supervised command of Captain George Van Orden and the firing party consisted of four distinguished Marine Corps. marksmen and a Chief Marine Gunner as the shooting coach.

The test took place on the afternoon of May 6 and the whole day on May 7, and consisted of instruction in the operation and firing methods of both types of rifles. Courses of fire at 300 and 1000 yards both slow and rapid fire were then shot. All shooters firing both M1 Rifle and Johnson Rifle at each stage.

Results concluded from the tests found that the Johnson Rifle was more accurate with a score of 81.2% total hits to the M1's 71.3%. There were no malfunctions with the Johnson Rifles or the M1Garands, however the M1's dropped their centre of impax during the test. The M1's were found to load and reload faster than the Johnsons but rate of fire in the rapid mode was identical with both rifles.

Capt. Van Orden's Summary Opinion stated "The Johnson Semi-Automatic Rifle, Rotary Magazine Type, is materially superior to the U.S. Rifle, cal. 30, M1 in accuracy and potential combat efficiency"

Rifles used for this test were: M1 Rifles - Serial Numbers 3536 and 3739

Johnson Rifles - Serial Numbers R13; R14 and R15 (all Rotary magazine models).

Further tests were held at San Diego in November of 1940 using four different rifles as comparisons. These were the standard '03 Springfield used as a "control", a Garand, a Johnson and a Winchester design ( which later went on to become the M1 Carbine). Results of these tests found that the Garand was the best rifle just beating the Johnson, the Winchester came in last. The Johnson was officially turned down in favour of the M1 Garand in early 1941. The decision was made mainly for logistical reasons, as the Garand was now in full production and spares were easily procurable from all Army Ordnance depots worldwide. (Below) A letter from General Wesson, Chief of Ordnance, to General Holcomb, Commandant USMC, referring to the San Diego rifle trials of 1940 in which the USMC's intentions are decided.

Click on image for full size view

Not being a man to give up easily, Mevin Johnson refined his design a little more and gave it the military sounding "Model of 1941" name. It is interesting to note here that the U.S. Military stopped using dates in their rifle nomanclature in the latter half of the 1920's. Had the Johnson rifle been adopted as a replacement or supplement to the Garand it would have been the "US Rifle, Caliber .30, M2".

An order was soon forthcoming for Model 41's. The Dutch Government in exile ordered 70,000 for use by their navy and troops in the East Indies. The order for these rifles was placed by the Netherlands Purchasing Commission. These rifles curiously, were produced in .30-'06 cal. instead of the standard Dutch 7.92mm (8mm Mauser). To meet this order Johnson Automatics in conjunction with Universal Windings of Providence, Rhode Island set up production facilities in nearby Cranston, RI, under the company name of "Cranston Arms Co. inc.".

The Johnson Factory in circa 1941, located at the UW Co. site in Cranston, RI

Soon after production had started, the newly created Marine Corps parachute echelons became interested in the Model 41 due to the easy ability of removing the barrel, a good feature in parachute drops. It was soon adopted for paratroop use and saw action with the marines in the Soloman Islands. These weapons were procured directly from the Netherlands Purchasing Commission, which by this time had embargoed the export to their colonies due to the Japanese overrunning them. One of these rifles has been seen with "US" stamped on it, probably done at local level by an armourer.

The Johnson met with mixed reviews with the marines, so loving its high rate of fire and reduced recoil and some hating it.One of the reasons for its unpopularity was the method of field stripping and the number of small internal parts which were easy to lose. It was also easier to procure spares for Garands due to their standardisation throughout the US armed service at that time. One of the things the marines did like about the rifle however was the ability to "top up" the magazine with either single rounds or five round stripper clips. This an advantage over the Garand which could only be loaded with the eight round en-bloc clip. The Johnson could also be loaded with the bolt forward on an empty chamber. It also proved very accurate at long range and with the reduced recoil it was less tiring to shoot than the Garand. Recoil being noted as approximately one third less than the M1.

At the wars end, the Marine Corps parachute regiments were disbanded and the remaining Johnson rifles on hand were collected at the Marine Corps Quartermaster Depot at San Diego, California, for return to the Netherlands Puchasing Commission. Seeing a good business opportunity, Melvin Johnson approached the Marine Corps Quartemaster at San Diego and bought back approximately 125 rifles for refurbishment. He then sold these at a profit via "American Rifleman" magazine.

Letterhead from Johnson Automatics stationary.

The only other sizeable order for Model 41 rifles came from the Chilean mounted troops (as noted in 'Rifles and Machine Guns of The World's Armies" by Melvin Johnson), who in 1943 ordered 1,000 of them in 7mm cal. the only difference from the standard .30-'06 variety was the barrel group. Barrels for these came from Mexico, however Johnson Automatics did contract with Hoffman Arms of Amarillo, TX to make these barrels but Hoffman's prices were to high.

Total production of Model 41 rifles is believed to be around 30,000 completed rifles, and 70,000 sets of parts (not receivers). This figure was from figures reported by Lt. Col. George M. Chinn in reports to the Ordnance board from figures supplied by Melvin Johnson. Approximately 3000 Johnson Model 41 LMGs were produced, verified from original ATF Form 2's.

In 1953 Winfield Arms Co. bought the bulk of the Dutch rifles as military surplus, shipping them to Canada with a view to future importation to the U.S. They also bought all of the available spares from Numrich Corp. (now Gun Parts Corp.), who had aquired them from Winchester after Johnson had sold out to WRA in 1952. After stockpiling the rifles, and refurbishing the broken ones, Winfield's imported them into the U.S. and sold them for $70 to $110 dependant on quality. Supplies finally running out in the mid 1960's.

Click above to see some Adverts from American Rifleman

Production figures are virtually non-existant however it is believed that total production was about 30,000 rifles but at this time a definite figure cannot be confirmed. Today a limited amount of original Johnson Automatics records still exists, mainly in the hands of collectors. The majority of the archive is missing or lost, perhaps destroyed in the huge fire at the Winchester offices in 1961. Original records, production documents and drawings do surface from time to time, usually from obscure sources.